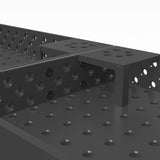

(Image shown is an example setup of a Siegmund System 16 3'x4' Imperial Welding Table Bundle. Table and accessories are not included and sold separately.)

The System 16 Welding Table Series is the ideal choice for fine detail applications.

All System 16 Professional Extreme tables feature the latest upgrades in aesthetics, versatility, and durability.

Our Double Hardened Tables are constructed from through-hardened steel before undergoing a Plasma Nitride treatment to provide you with a table of superior quality and performance.

- The materials used are fundamental to the high level of hardness and long service life.

- With a Siegmund® table, you will experience long-term savings, thanks to the high level of precision engineering, as well as the consistent superior quality.

- Side surface of Professional Extreme 8.7 is made of specific basic material S355J2+N incl. plasma nitriding and BAR-coating.

The hardened X7 Steel (the 8.7 Series), is specially made for Siegmund in Germany. This steel is of a considerably higher hardness grade compared to 98% of the welding tables in the market. The only thing harder to our 8.7 series table are our Siegmund 8.8 Series Welding Tables. With the Series 8.7 Siegmund Welding tables, the top plate achieves a hardness of 850 vickers after the Plasma Nitration and the BAR-Treatment. The higher hardness also helps maintain the flatness of the weld table.

Specs and Features

of the System 16, 8.7 Imperial Series Welding Tables

Specs & Features

of the System 16, 8.7 Imperial Series

Welding Tables

Welding Table Specs and Features:

- Overall Tabletop Size: 3' x 4' (36" x 48")

- Borehole Diameter: Ø 16mm (5/8")

- Welding Table Series: Professional Extreme 8.7 Series

- Welding Table Material Thickness: Approx. 7/16" to 1/2"

- Welding Table Material Type and Finish: Professional Extreme 8.7 Hardened Tool Steel, Plasma Nitrided and BAR-Coated

- Table Surface Hardness: 450-850 Vickers

- Official Siegmund Welding Table Part No.: US160025.X7

- Maximum Weight Load: 5,380 lbs. (Based on Even Distribution)

- Approximate Table Weight: 486 lbs.

- Boreholes on the Surface are a 2"x2" Inch Grid Configuration.

- Boreholes have a diameter of 16mm (5/8"), Boreholes have a 1/16" Radius.

- Radius 1/10" on the table edges and 1/4" on the corners.

- Height of table side is 3-5/16" - Borehole in Diagonal Grid.

- INCH Scale Engraved on the Surface.

-

Bottom of Structure has Reinforced Ribbing.

Welding Table Leg Options

Part Numbers, Specs and Pricing

Welding Table Leg Options

Part Numbers, Specs and Pricing

Siegmund Welding Table Leg Options Chart

| Leg Type | Item No. | Capacity Per Leg | Leg Height | Table Height | Cost Per Leg |

|

1. Standard Leg |

US160858.X |

2,200 lbs. |

32" |

36" |

Included |

|

2. Height Adjustable Leg |

US160877.XX |

2,200 lbs. |

22"-38" |

26"-42" |

$85 |

|

3. Leg with Casters and |

US160876.XX |

440 lbs. |

32" |

36" |

$94 |

|

4. Height Adjustable Leg |

US160879.XX |

440 lbs. |

24"-36" |

28"-40" |

$142 |

Siegmund System 16 Welding Table Leg Options - Full Specifications

1. Standard Siegmund Leg(s)

- Item No.: US160858.X

- Leg Height: 32"

- Table Height: 36"

- Fine Adjustment: 1-5/8"

- Capacity Per Table Leg: 2,200 lbs.

- Cost Per Leg: $0 (Included with Welding Table as a Standard)

- Cost Per 4 Leg Set: $0 (Included with Welding Table as a Standard)

2. Height Adjustable Siegmund Leg(s)

- Item No.: US160877.XX

- Leg Height (Adjustable): 22" - 38"

- Table Height (Adjustable): 26" - 42"

- Fine Adjustment: 1-5/8"

- Capacity Per Table Leg: 2,200 lbs.

- Cost Per Leg: $85

- Cost Per 4 Leg Set: $340

3. Siegmund Leg(s) with Casters and Locking Brakes

- Item No.: US160876.XX

- Leg Height: 32"

- Table Height: 36"

- Fine Adjustment: 1-3/16"

- Capacity Per Table Leg: 440 lbs.

- Cost Per Leg: $94

- Cost Per 4 Leg Set: $376

4. Height Adjustable Leg(s) with Casters and Locking Brakes

- Item No.: US160879.XX

- Leg Height (Adjustable): 24" - 36"

- Table Height (Adjustable): 28" - 40"

- Fine Adjustment: 1-3/16"

- Capacity Per Table Leg: 440 lbs.

- Cost Per Leg: $142

- Cost Per 4 Leg Set: $568